Industrial Machine Upgrade

Client: Local Brisbane Manufacturer

Technology: Rockwell L7 and Safety Partner PLC’s & Wonderware HMI/SCADA

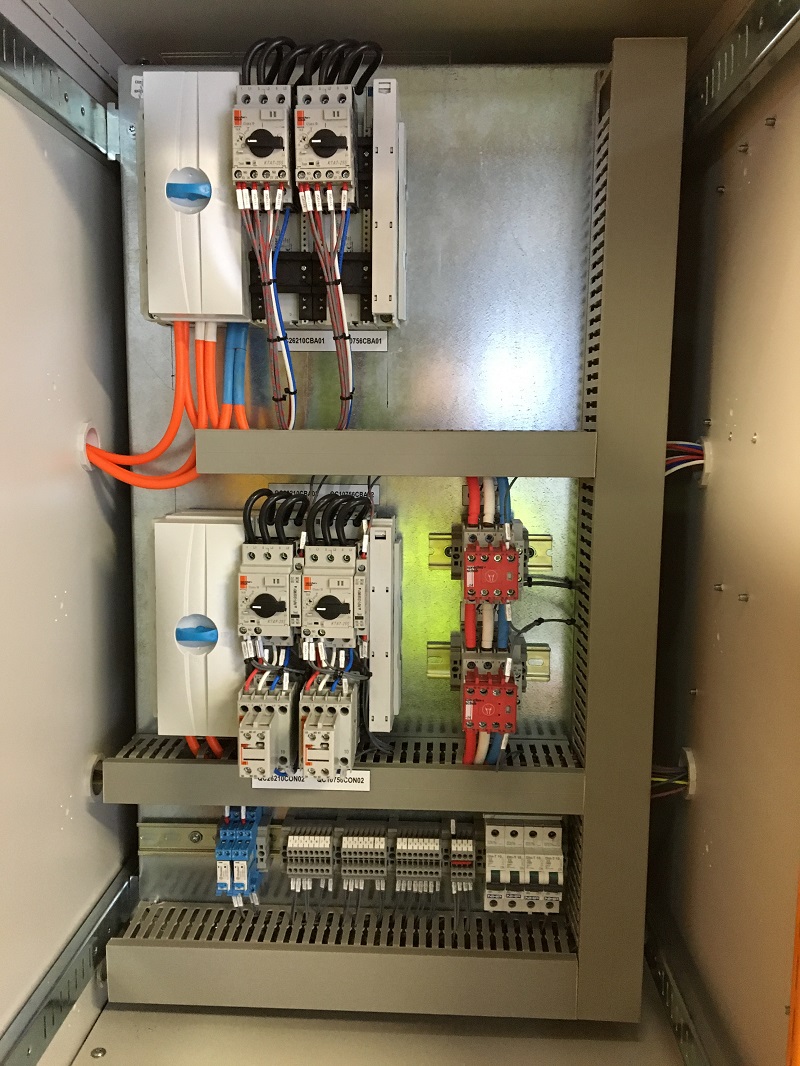

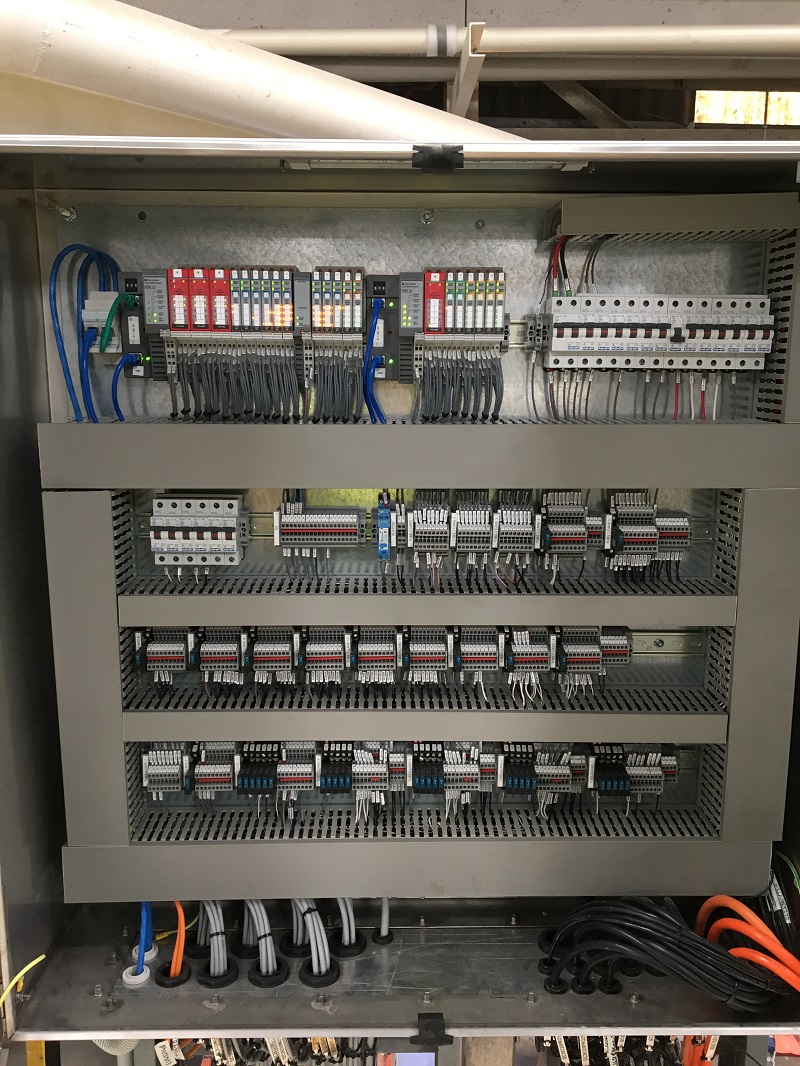

Through increased demand there was a business need to increase production capability at the plant. The decommissioned machine was rebuilt with new NHP supplied Cubic Arc Flash Switchboards, PLC’s, instrumentation and incorporated many process design technology improvements.

Witthoft Engineering were responsible for the Electrical Power and Control System Design, PLC and SCADA Programming, and commissioning. Power System Analysis was also completed within the Electrical Design to incorporate for Arc Flash rated electrical switchboards.

Witthoft were also responsible for the design, verification and commissioning of the Electrical Safety System comprising of:

- 16 Emergency Stop signals

- 15 Gate Monitored devices

- A Lanyard system

- 5 Fortress Gate Interlock units

These were all integrated into a Rockwell Safety Partner PLC to Safety Performance Levels ‘PLc’ and ‘PLd’.

The final design included:

- Over 450 Autocad drawings

- 540 physical I/O connections

- 57 motors

- 15 Danfoss Drives

- 2 SEW Drives

- The development of the Machine Functional Specifications

- Interfacing to 3 other PLC systems upstream and downstream

Witthoft engineers were also involved in the Ethernet network design and commissioning of modifications to plant ethernet network.

The software was extensively simulated and tested to customer requirements prior to site commissioning.